Chalk Talk Recap: Why Paper Mills will benefit from pairing Near-Infrared LEDs with Cameras

For those of you that missed our first episode of Chalk Talk with Brian Mock, we want to get you up to speed on some of what was covered. Each month, ECS will take you on a deep dive into what paper makers want to hear.

What are the best practices and challenges to maximizing one of the most valuable tools you have to stay competitive in today’s marketplace?

The answer is simple, your camera quality control systems - also called machine vision systems.

The systems that we are referring to are where the camera is still working, the backbone is still there, and it is providing some level of awareness to the operators. Time and time again, the paper mill is where camera lighting technology goes to die leaving the camera in a light starved condition - not working at the correct depth of field, shutter speed, or contrast. Also at some point, the LED stops working entirely, rendering the position completely useless.

While we at ECS have services to help with the entire paper making process starting from wood chip quality control to laser inspection once you have your finished product, the part of the process that we are talking about here is on the paper machines and converting lines.

Below we have a chart that showcases what we call the Building Block Funnel of WMS and WIS Solutions. Each of these 10 factors plays a major role in operator utilization which then leads to increasing your overall efficiency and reducing waste and delay. Whenever there is an issue at any part of this funnel, you will start to lose across the board. While eventually we will discuss all of this, our focus today is on optimizing the LED technology that you are pairing with your camera systems.

Before we can delve directly into why Near Infrared LEDs are the superior technology to pair with your cameras, we first need to discuss how the system works as a whole. The main performance factor that we care about when talking about these systems is called Maximum Even Lumens on Target (MELT).

MELT is the key factor to generate the correct shutter speed, contrast, and depth of field. Resolution is paramount to operators and image processing tools, helping them to better identify the cause of a paper break or to identify an issue before the paper break happens in the first place. The quality of the pixels that you are getting from your camera system is directly correlated to helping your mill run at peak efficiency.

When you think about how a vision system is set up at a paper mill, you have the camera mounted with an LED that is facing some portion of a paper machine, looking through a layer of steam coming from the machine. This steam plays a huge role in the quality of resolution that your camera is able to capture when it is viewing this region of interest (ROI).

With a Broad Spectrum LED, the light travels to the steam, reflects back to the camera, and in turn provides the camera a layer of white light energy that clouds your resulting image. This lesser quality image now is not providing you the ability to view what is going wrong underneath.

Near-Infrared LEDs

This is where the Near-Infrared LEDs (NIR) as our solution, come into play. At the frequency range that we use, the wavelength is longer which is able to penetrate the steam, reflect off of the actual target, and be picked up by the camera in higher fidelity. Here’s the catch, not every NIR will actually be able to achieve this result which is where our secret sauce lies.

Remember where we talked about shutter speed before. When cameras are taking video, they are actually turning themselves on and off at a rate of speed of 60 frames per second or higher in some cases. In a traditional system, the LED is on continuously while the camera is turning on and off. This actually creates excess power waste from the LED and problematic heat that can lead to a shorter life for the LED.

Our NIR system pairs to the shutter speed of your camera, strobing on and off in tandem at a much higher and more concentrated intensity that allows the light to push through the steam much more efficiently while also saving power and heat which we call, Hammer Drive.

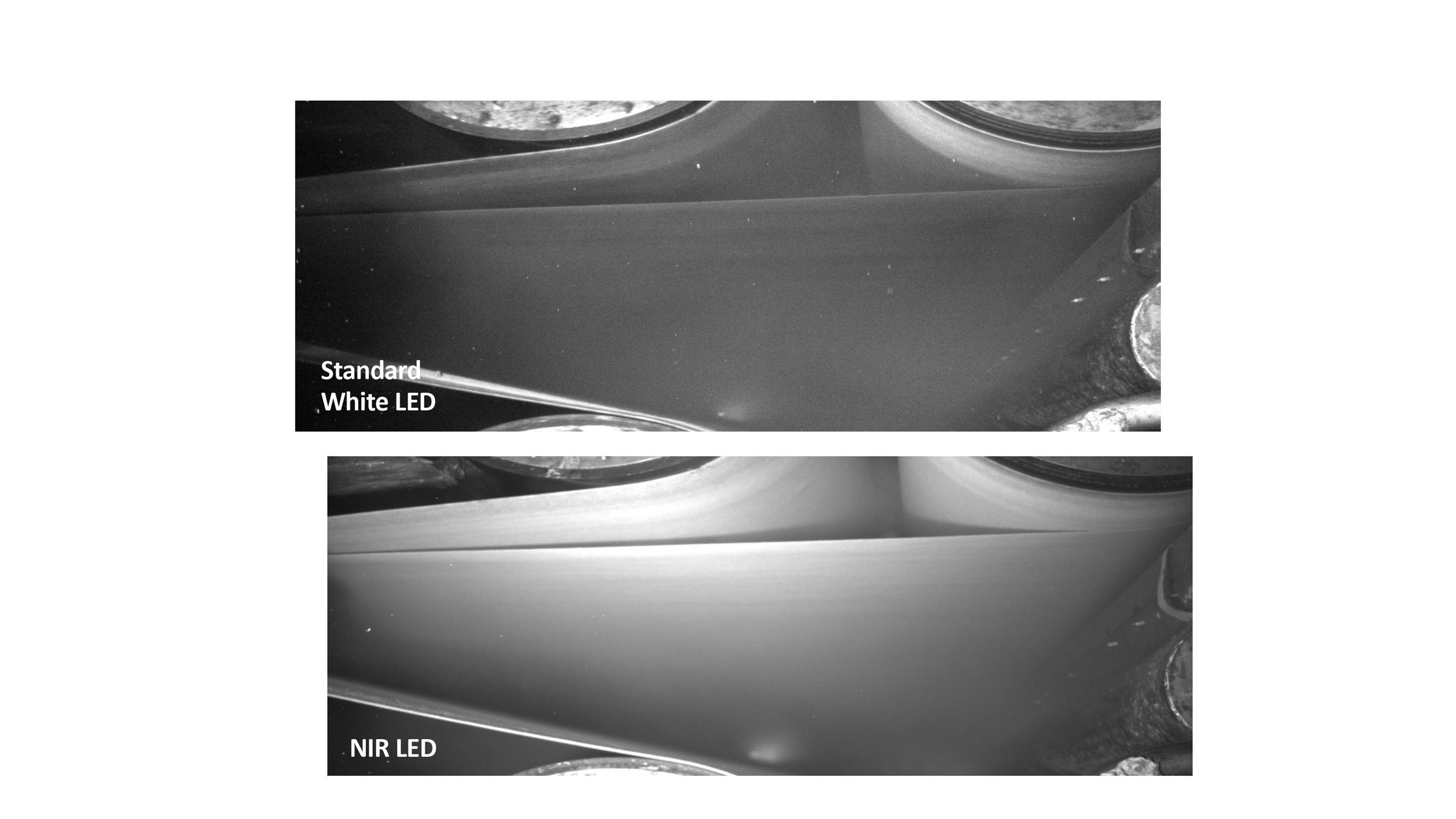

The other main differentiator is in the way that we construct the LED. Our build has two main advantages. First, we are able to cluster the 256 LEDs together in a super compact manner by removing the reflectors from the board and utilizing a fresnel lens to focus the energy. Secondly, there are no electronics on the LED board that would lead to it overheating. The fresnel lens allows us to evenly distribute the energy created that in turn makes perfectly even lighting which you can see in the image comparisons below.

It is vital for us to stress the importance of how without the presence of electronics, our light head can exist without air inside your dryer section up to 200 degrees fahrenheit. This is achieved by adding pressurized air with a vortex cooler, providing operation above 200 F. There is nothing to burn. The driver and remote power supply are remotely located which gives the unit this advantage. We have seen it time and time again at paper mills where the lights are out because someone disconnected the air or water and weeks or months go by before they figure out why this has taken place.

The glass on our unit is also completely smooth to allow you to easily wipe it down or provide water to a continuous cleaning nozzle. Now you know that it is not only the technology behind the unit but also how you house it, deliver it, and make it survivable in these harsh conditions.

Now that you have all of these factors covered, there is still one massive difference between the two kinds of lighting sources. NIR energy is monochromatic while Broad Spectrum is exactly as the name suggests. Broad Spectrum lighting reflects all the visible light to human eyes, leading to the cloudy image that you have seen.

When NIR is reflected off of surfaces, the reflection is actually brighter with a higher degree of contrast to the camera that is capturing this event. Operators have to use a multitude of different Broad Spectrum LEDs just to try to capture an event that one NIR LED could capture on its own and even then, the NIR outcompetes. An example of such a shot is provided below.

When would I use Near-Infrared LEDs?

The short answer is, always. From paper, to tissue, to bown board, NIR is ideal in any kind of paper that you make.

How much do NIR LEDs cost?

Our biggest and most optimal Near-Infrared 256 LEDs will cost at a range of $5-7K per LED.

Can I use it on non-ECS camera systems?

Yes

The Bottom Line

You now have a grasp on why Near-Infrared LEDs are the ideal choice for your paper mill in any instance. We at ECS have spent years perfecting this technology so that you as operators can increase usability and efficiency of your current vision systems. This was a synopsis of everything that our President, Brian Mock, covered in his presentation. If you want to check out the full video with even more detailing, you can check that out on our Youtube channel here. For those of you that want further information regarding these systems and how we can help optimize your paper mill, reach out to us and we will take care of you. If you enjoyed this read, share it with your friends in the paper and pulp industry so that they can learn about it too.

Thank you for taking the time to keep up with us here at Event Capture Systems. Look for more insightful content from us in the coming months! See you then.